Product Description

Free Shipping

Dialux Brand polishing compounds originally formulated in France has been a popular polishing compound for over 50 years.The Dialux® polishing compounds are a high grade premium polishing line of compounds specifically formulated for Precious Metals in Jewelry Polishing.

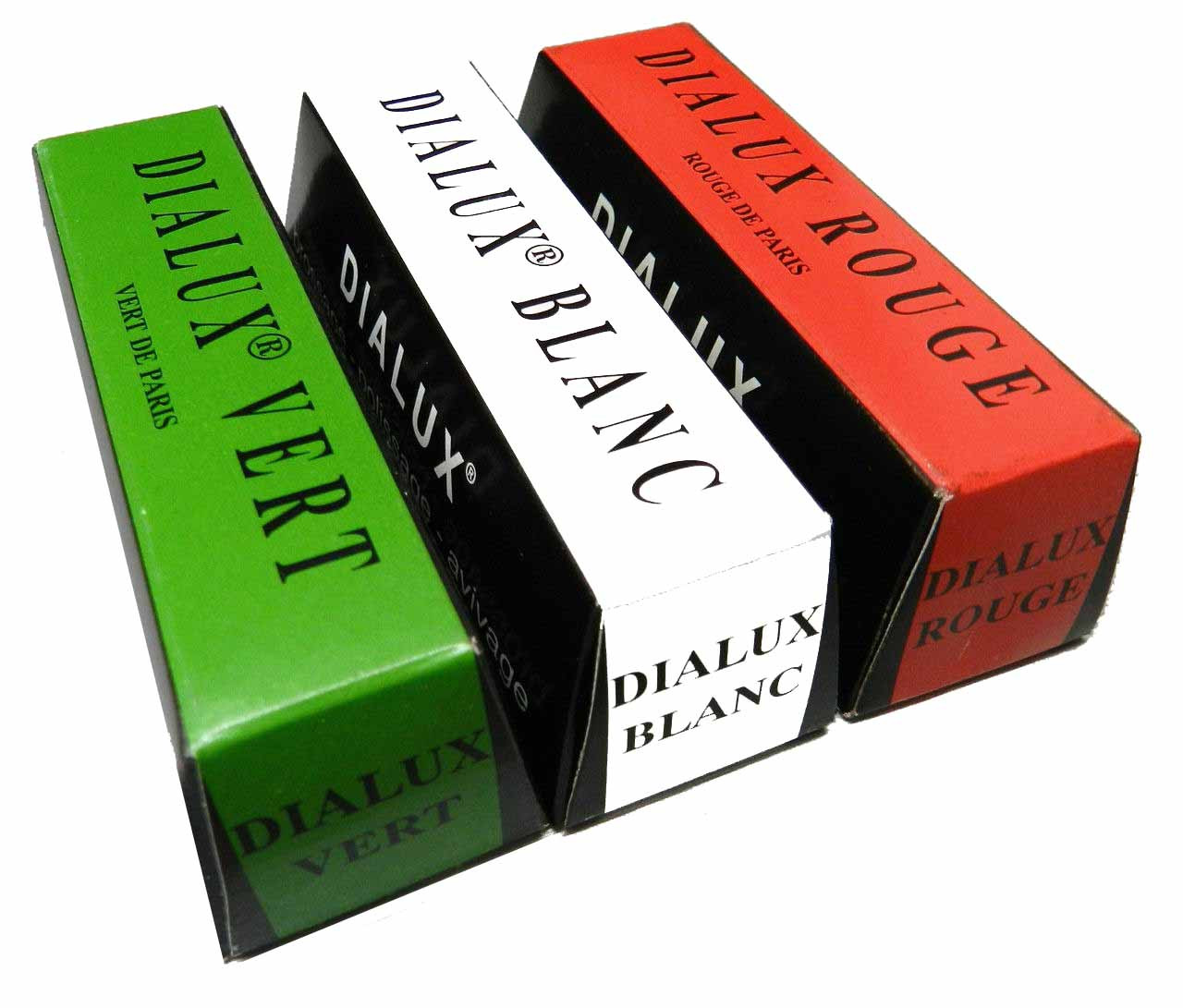

VERT - GREEN

- VERT - GREEN Dialux is an all around premium polishing compound formulated for White Metals and Hard Metal Alloys. The Dialux polishing compounds are a high grade premium polishing line of compounds specifically formulated for Precious Metals in Jewelry Polishing. Dialux® Green works with White Gold, Silver, Stainless and Chrome Alloys and can be used for Platinum.

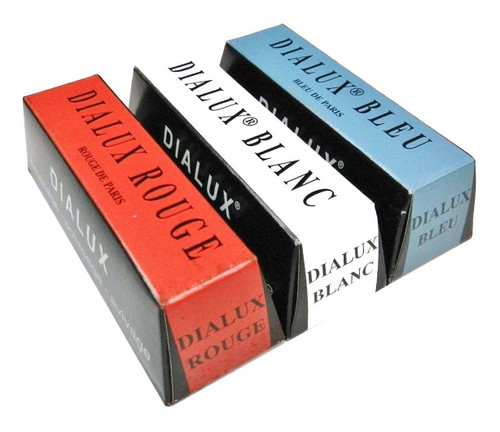

BLANC - WHITE

- Dialux® BLANC-WHITE Polishing compounds a premium compound for white metals. Dialux White is formulated especially for Silversmiths and Goldsmiths to polish White Gold, SILVER. The Dialux White is widely used by Metalsmith’s for a High Polish Finish. Use a small amount of this compound on a Muslin - Finex - White Buff, make sure buff edge is clean for best results. Used for Bright Polish on White Metals - Gold - Silver

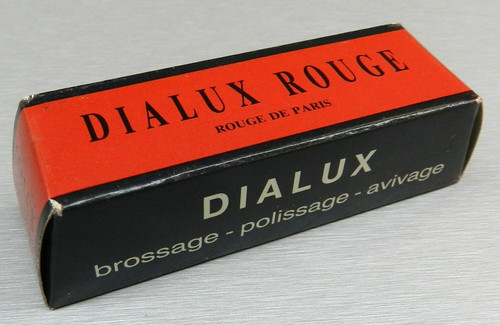

RED - ROUGE

- DIALUX® RED ROUGE Brand polishing compound is the originally Gold Polishing compound formulated in France, it is the most popular polishing compound for Yellow Gold for over 50 years. The Dialux® polishing compound is a High Grade premium polish to bring out the Highest Shine and Glow for Jewelry. ROUGE is specifically formulated for Precious Gold Metals in Jewelry Polishing.

Specifications:

- Bar size: 4" x 1" x 1-1/8" - 100mm x 25mm x 30mm

- Bar Weight: 120 Grams - 4 Oz.

- Bars are individually wrapped like Chocolates

- Utilizes Graded Abrasives

- Blended with Additives

- Long Lasting Composition with Minimum Usage

- Good Adhesion to Buffing Wheels

- Produces - High Luster - High Shine

POLISHING RECOMMENDATIONS:

Our recommendations and suggestions on Buffing to obtain the best results possible:

- Use the right compound for the metal that you are trying to polish

- It may be needed to go through 2 or 3 steps, in polishing to get the optimum result you are looking to achieve.

- Make sure that the parts that are being polished are smooth and clean, use the appropriate abrasive to remove lines and scratches.

- Avoid using different compounds with the same buff, if you have to then make sure to clean and remove any hardened compound residue on the surface edge with a buff rake.

- Segregate your buffs for the various metals, Gold, Silver, Brass … try not to use the same buff for all metals. If you have to then make sure buffs are cleaned (dressed) with a buff rake.

- A clean buffing wheel edge is important.

- Allow the buff and compound to perform the work they were made and formulated for, excessive force or pressure will hurt the process.

- Whenever you are working with Platinum never use a buff that was used for another type of metal.