Product Description

Free Shipping

The Delft Clay Method is a highly refined form of sand casting that substitutes genuine Delft Clay from Holland for ordinary casting sand. Reproduce your original models quickly with this unique Delft™ clay casting system. Keep the traditional techniques of sand casting alive and well with this re-usable, ultra-fine Dutch clay mix.

The process was invented by Hans Karreman, a Dutch goldsmith. Delft Clay is much finer than casting sand, providing remarkably sharp and highly detailed castings in gold, silver, copper-based alloys, pewter, etc.

Castings require very little finishing work. Once you have cast your piece, the Delft Clay can be re-used. Since this is a cold-molding process, molds can be made from patterns composed of wood, wax, epoxy, plastics, and, of course, metal. Because this is a type of sand casting, it is best suited to producing castings without pronounced undercuts.

Specifications: JETS Product # 0305-3002

- Delft Clay 2 Klio (4.4 lbs.)

- Country of Origin: Netherlands (Holland)

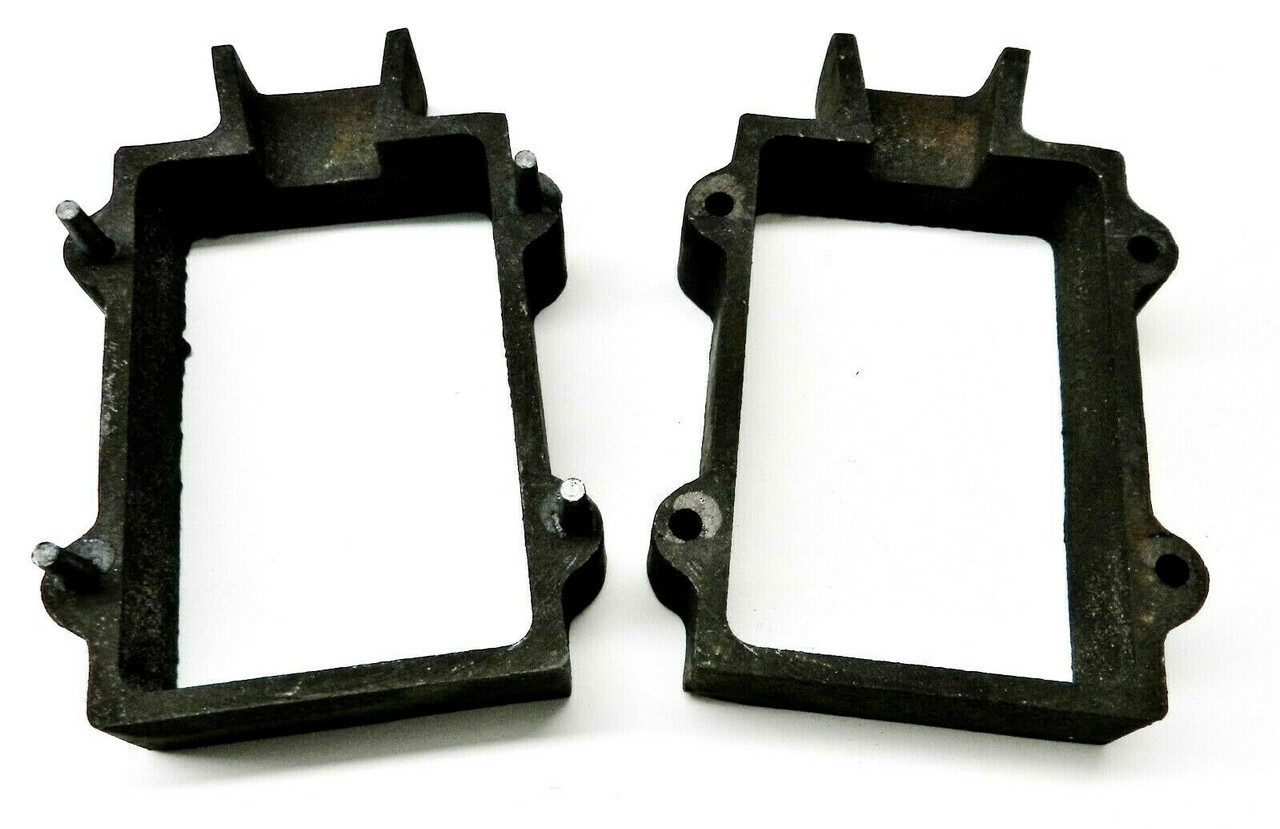

- Casting Frame made of cast iron is a sturdy iron flask for sand casting. It is an ideal vessel for casting with Delft Clay or sand.

The 2 Part frame attaches together with 4 holding pins, allowing you to easily duplicate various forms and shapes, jewelry pieces, and more…

Specifications: JETS Product # 0305-200

- Metal: Made of Cast Iron with 4 Guide Pins

- Overall Dimensions: 6-1/4" x 4-1/4" x 2-1/4"

- Cavity Length: 4-1/2"

- Cavity Width: 2-7/8"

- Cavity Depth: 2-1/4" (1-1/8" Each Section)

- Wall Thickness: 9/32"

- Pouring Spout Opening to Cavity: 1"

- Weight: 3.2Lbs.

INSTRUCTIONS: Delft Clay mold is created in these steps:

1. Fill and compact the Clay into one half of the frame

2. Remove excess clay with a straight edge (e.g. a flexible steel ruler)

3. Press your original pattern halfway into the clay.

4. Brush Mica Powder or talcum powder over this surface of the mold

5. Install the other half of the frame, fill with clay and compact

6. Open the frame and remove the pattern

7. Carve out a pouring channel and vents

8. Pour in molten metal The Delft Clay Casting