Product Description

Free Shipping

Soldering brazing all purpose, low temperature flux Handy® Flux is a long lasting white paste type, very durable won’t break down from prolonged heat, an all-purpose flux for use in brazing and soldering Gold, Silver, Brass, Copper and other Non-Ferrous Metals.

Handy Flux is an active fluoride/borate-type flux which is appropriate for all nonferrous metals and begins to melt and dissolve oxides at 600°F, having an effective temperature range from1100° F-1600° F. Paste formula can be cleaned up with hot water.

Prior to soldering make sure joints and the solder are clean, flux the full surface area to prevent oxidation and allow for good solder flow, and a good brazed joint.

Soldering Note: Clean - Surface & Joint is important and not too much Solder, good even heat over entire joint area. Clean remove oxides and other soldering residues prior to finishing.

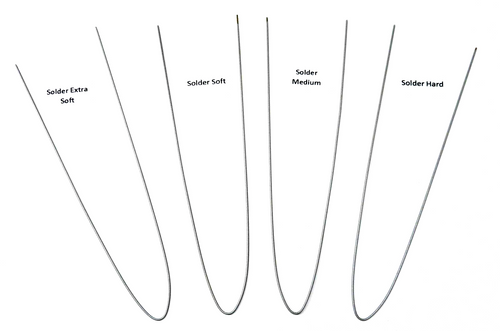

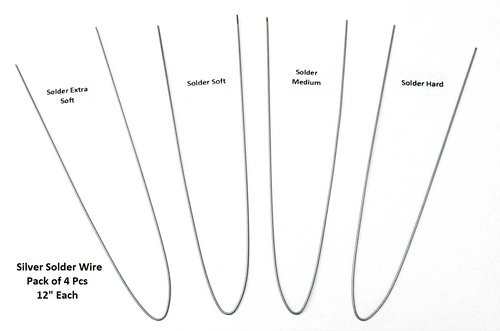

Silver Solder Wire used in Jewelry Making, Repair work such as sizing and mounting, for assembling silver jewelry, rings and components.

Silver solder comes in 3 grades… the grades are the relative temperature flow points between one and the other. The softer the solder the less content of silver with a lower melting temperature.

SALE is for Handy Flux a 7oz. bottle with Brush and 3 GRADES of SILVER Solder Wire, (Soft, Medium and Hard) 5 Feet long of each grade each, weighting approximately 1/4Toz). - 4.85 Dwt (Total sale for 15 feet - 3/4Toz.)

Soft/Easy Specifications: JETS Product # 1924-407+1925-452-SMH

- Solder WIRE: Silver Content of 65%

- Melt temperature: 1,240°F - 671°C

- Flow temperature: 1,325°F - 718°C

Medium Specifications:

- Solder WIRE: Silver Content of 70%

- Melt temperature: 1,275°F - 691°C

- Flow temperature: 1,360°F - 738°C

Hard Specifications:

- Solder WIRE: Silver Content of 75%

- Melt temperature: 1,365°F - 741°C

- Flow temperature: 1,450°F - 788°C

Technical Information: NOTE: Cadmium FREE Solder -Solder Wire Thickness: 20ga - 0.032” - 0.81mm

Attention: These solders are made to be used with high heat torch or butane torch in order to reach melting temperature, it is not intended to be used with soldering iron.

Repairs: Lower temperature solder is recommended for repair work, especially on pieces that may have been reworked and a high temperature solder may cause a problem.

Assembly Work: In multiple component soldering use the Higher Temperature Solder first, then a medium grade and finally to a soft the lower melting point.

Production: High temperature solder, the hard grade should be used, with the higher silver content, better match of color and a stronger bond. Allowing future repairs to be performed with the softer solders.